After the end of the Great Patriotic War, the head enterprise in Moscow continued to manufacture the transitional model ZIS-50 (ZIS-5 with a 90 hp engine) for another two years, while in 1951 UralZIS in Miass replaced ZIS-5V with the improved model ZIS-5M having a 77 hp engine The lack of gasoline in the war-torn country and lots of waste wood in the Ural and Siberia regions forced the automobile plants to design and produce gas-powered vehicles. In 1949-1950, the Central Scientific Research Institute of Mechanization and Energy of the Forest Industry of the USSR (TsNIIME) designed and tested several prototypes of charcoal gas generating units TsNIIME-16 for UralZIS-5M vehicles and later offered more advanced Ural-ZIS-332 units. However, when engine runs on wood gas, its power inevitably decreases down to only 45 hp while the load capacity of UralZIS with the gas generator drops by 500 kg. However, a truck equipped with a TsNIIME-16 gas generator unit successfully passed the test run from Moscow to Minsk and back, and since gas generators still remained very attractive in those days, in 1950 NAMI created the gas generator vehicle UralZIS-NAMI G-78A on the basis of TsNIIME-16.

In the post-war period, the urgent need for specialized vehicles forced the engineers to use the UralZIS-5M chassis in dump trucks UralZIS-351, watering and washing machines MPM-1, garbage trucks MS-1 and, of course, fire trucks PMZ-11A. Most of ZIS-5s manufactured in Moscow were either damaged during the war or completely worn out by the beginning of the 50s. However, lots of such vehicles continued to serve in the country's automotive fleet until the seventies, and almost all of them had the shield logo of UralZIS on their the upper radiator tank.

The three-ton trucks from Ural were significantly improved and had many differences from ZIS-5 and ZIS-5V vehicles produced by the automobile plant in Moscow. Since January 1944, the designers and engineers increased the compression ratio up to 5.3, modified the shape of the intake pipes and installed the carburetor MZK-6V. Since 1947, the trucks UralZIS-5V were equipped with three drop sides of the flatbed instead of only one. In 1949, the vehicles were updated with a hydraulic brake drive, and in 1950 the engineers reinforced the rear axle gearbox, installed a new muffler and moved the gas tank from under the driver's seat to the left stiffener of the frame under the vehicle's body. The beginning of the fifties saw a wide range of innovations, such as a reclining spare wheel holder, an interrupter, a distributor with a centrifugal vacuum regulator, and reinforced axle shafts. Then, thanks to the compression ratio of 5.7:1, thin-walled liners used for the connecting rod and for main bearings, as well as chrome-plated upper piston rings, the engine of ZIS-5M was boosted up to 85 hp and the truck's top speed increased up to 70 km/h without any loss of the engine's high flexibility. Such flexibility enabled this vehicle with the minimum speed of 5.8 km/h.

All these changes have significantly improved the quality and performance of the vehicle. However, the model index remained the same, and many drivers even thought that the vehicle produced in the fifties was no different from that from the thirties, manufactured by the automobile plant in Moscow. In the first quarter of 1956, the design of ZIS-5M was updated again with improved units: new steering elements, a larger gas tank, a preheater, and more. The upgraded vehicle produced at the Ural Automobile Plant since the beginning of 1956 got a new model index: UralZIS-355. The truck's exterior featured the streamlined rounded front fenders and the refreshed wheel disks. UralZIS-355 once again became the basis for dump trucks, truck cranes and tank trucks — but this time without fire-fighting attachments.

Hard-working engineers of the Design and Trials Department headed by A.S. Eisenberg, the former engineer from ZIS hired by the Automobile Plant URAL, began to think about the future development of the model range right after the end of the war. And already in 1948, they introduced a prototype of UralZIS — with a wooden cabin, a streamlined hood, and front fenders. The vehicle was officially named “Modernized UralZIS”. It was equipped with a forced 87 hp engine, a drum parking brake, a propeller shaft on needle bearings, and a hand-made cabin with a wooden frame — simply because the plant did not have any pressing or stamping equipment back then. This prototype laid the foundation for another two new UralZIS machines with the load capacity of 3500 kg. Later, they were tested at NAMI, but their layout was criticized by the NAMI experts: it was necessary to push the cabin deeper onto the engine to increase the flatbed and shorten the wheelbase. All their suggestions were taken into account and implemented in the next prototype called UralZIS-353. The vehicle got a new 95 hp engine working at 2,600 rpm and featuring a new layout with a simplified auxiliary drive and the compression ratio of 6.0:1. UralZIS-353 got an alligator-like hood, a cabin with a heater and ventilation, and fenders similar to those in GAZ-51.

The management of the Automobile Plant URAL was about to launch the new truck into production, but could not set up the manufacturing of all-metal cabins due to the lack of stamping equipment. A workaround was found by Andrey Lipgard, who was serving his exile in the Urals back then. He analyzed the situation and suggested using duplicated stamps from GAZ trucks for the manufacture of the cabins. In 1955, four new UralZIS-353 vehicles and the modification UralZIS-354 based on the gas generator successfully passed factory tests.

In 1954 and 1955, the Automobile Plant URAL took part in the Exhibition of National Economy Achievements of USSR and was awarded several medals. On June 13, 1956, the vehicles set off for interdepartmental tests on routes Miass — Moscow — Alushta — Yalta — Simferopol — Moscow — Miass with a total length of 25,000 kilometers. When the tests ended, the Minister of the Automotive Industry ordered to launch the mass production of UralZIS-355M since the third quarter of 1957. Unfortunately, due to the lack of funding and experience at the Ural Automobile Plant, the serial production was postponed by almost a year.

In addition to the cargo truck and gas generator truck, in October 1957 the plant also presented the three-way dump truck UralZIS-358 — an all-wheel drive modification of UralZIS-381 with a transfer case and a front axle adopted from GAZ-63. The UralZIS-355M chassis was used in combination with many specialized bodies, both factory-made and custom. The most popular modifications include milk tankers ATsM-2.3 produced by the Novotroitsk machine-building plant, the fuel tankers ATs-2.6-355M produced by the Emanzhelinsky mechanical plant, the sewage trucks ANM-355M, and the mobile compressor stations APKS-6P-8.

Initially, UralZIS-355M was intended for delivery to the virgin lands, but gradually gained more and more recognition among motor transport workers throughout the Soviet Union. Drivers liked its warm all-metal cabin with a modern heating system, electric windshield wipers and other conveniences missing in ZIS-5. Though not so common in Moscow, Leningrad and other large cities, UralZIS-355M has become the basic vehicle in the truck fleet of Voskresensk near Moscow. The All-Union Foreign Trade Association “Avtoexport” created in 1956 started to offer the truck to foreign buyers, but most of them didn't want to purchase an intermediate model between ZIL-164 and GAZ-51 — however, some UralZIS-355M were sold to Finland and Afghanistan.

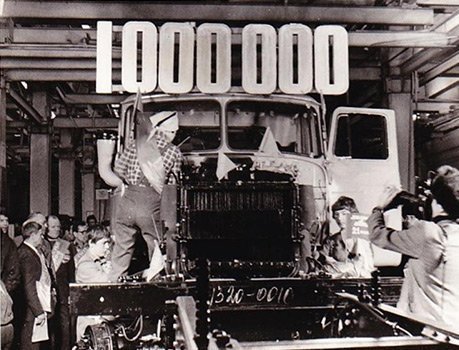

The last UralZIS-355M was released on October 16, 1965. Thus, the basic layout of ZIS-5, though transforming over the years, was used in the production of trucks for 34 years.

The fifties saw the beginning of the auto racing history of the Automobile Plant URAL. In October 1957, the all-Union motor sport competition was held in Rostov-on-Don. The event saw 98 vehicles ZIL-150, GAZ-63, and GAZ-51, including six vehicles UralZIS-355V. Though pilots from the Ural Automobile Plant didn't have much experience in such competitions back then, they managed to compete successfully even with the most seasoned drivers. The Ural team took all the first places. In the individual championship, the first place and the title of USSR champion were awarded to the crew of driver P. Terentyev and his mechanic

Automobile Plant

Automobile Plant